StandardAero offers Factory-Authorized airframe service and maintenance on all Dassault Falcon aircraft. As a matter of fact, we have completed over 50,000 inspections on these aircraft. We can perform everything from minor repairs to major alterations at facilities throughout our service network. Our facilities include Class 4 Repair Stations, with ODA (Organization Designation Authorization) and EASA (European Aviation Safety Agency) ratings, as well as various other international ratings.

As always at StandardAero, we are continuously looking to develop proprietary workflow and repair processes that can help to reduce your costs and downtime. Plus, you can count on a dedicated member of our staff to keep you informed about the progress of your airframe service helping you to make informed, confident maintenance decisions.

Falcon 900/2000/50 and Hawker 800 business jet owners want to cut fuel consumption, increase range, fly faster at the same rate of fuel burn and climb faster to cruising altitude – making their aircraft look sleeker and increase its market value.

StandardAero has been a long-time authorized installer for Aviation Partners® Blended Winglets™, which do all of that and more. Contact your sales representative to obtain pricing, availability and downtime

StandardAero is an Organization Designation Authorization (ODA), FAA/EASA approved Class 1-4 repair station and is a Dassault Authorized Service Center.

Falcon 50 and 50EX owners want to continue operating their aircraft past its 30 year in-service life limit.

StandardAero performs a thorough review of aircraft documentation in support of Dassault Aviation Falcon 50 Service Bulletin 460-R1 to maintain aircraft airworthiness regarding corrosion damage.

The Dassault Corrosion Protection and Control Program (CPCP) entails a systematic review of aircraft records in support of Dassault Aviation Falcon 50 Service Bulletin 460. This provides Falcon 50 owners with documentation to present to their local airworthiness authority enabling them to maintain aircraft airworthiness past the 30 year in-service life.

The Corrosion Protection and Control Program is designed and intended to monitor corrosion in the airplane’s primary structure in order to control any structural loss due to corrosion in order to maintain airworthiness.

CPCP is part of the Falcon 50 and 50EX life extension program. Compliance with Service Bulletin F50-460 consists in determining whether the aircraft is in “STANDARD” or “NON STANDARD” condition by establishing a Justification File based on the requirements of this Service Bulletin. Dassault defines corrosion classifications in 05-40/00 page 6.

As authorized service centers, StandardAero facilities have more experience with Falcon inspections, resulting in lower down time and better work quality. In fact, SA Springfield is one of the largest Falcon Authorized Service Centers.

CPCP works in conjunction with the Supplemental Structural Inspection Program (SSIP) which extends the life of these aircraft past 20,000 cycles / 30,000 hours.

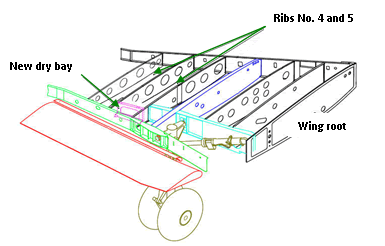

Dassault has elected to modify Falcon wing design, to provide the safest business jets available. This safety improvement is currently installed on in-production aircraft. Dassault has a retrofit solution that has been developed via Service Bulletin (SB) F50-496, F2000-358, F2000EX-171, F900-388 and F900EX-329. It is anticipated that an airworthiness directive will be issued by the EASA in the first quarter of 2010 to mandate compliance with these Service Bulletin’s (FAA is also expected to issue an A.D. at a later date).

StandardAero became the first authorized independent service center in North America trained to perform wing tank (dry bay) modifications on the Dassault Falcon 50, 900 and 2000 aircraft.

StandardAero’s Dassault-Authorized Service Centers are factory-trained, equipped and proficient at performing this complex structural rework activity. To date, StandardAero has successfully completed 8 Wing Tank Modifications. StandardAero is a Falcon Total Care Service Center – This modification can be completed along with any scheduled airframe or engine inspection, or in conjunction with an engine, airframe, avionics, paint or interior upgrade.

Augusta, GA

Augusta Regional Airport / Bush Field (AGS)

1550 Hangar Road, Augusta, GA 30906

Phone: +1.706.793.5600

Houston, TX

George Bush International Airport (IAH)

17250 Chanute Road

Houston, TX USA 77032

Phone: +1.281.230.7800

Springfield, IL

1200 North Airport Drive

Springfield, IL USA 62707-8417

Phone: +1.217.544.3431

AOG Hotline: +1.217.535.3560.

These Standard Terms and Conditions of Sale for Services (“Terms and Conditions” or “Terms”), together with the terms of sale of the services (“Services”) as set forth in StandardAero’s catalog, quotation document, or other StandardAero communicated offer document (to be known herein as “Quote” or “Offer”) will comprise the entire agreement (“Agreement”) between the Parties for Services on Customer’s components or accessories (collectively “Components”). In this Agreement, “Customer” refers to the entity listed on StandardAero’s Quote. StandardAero and Customer may be individually referred to as a “Party” or collectively as “Parties”.

Asian Surface Technologies Pte Ltd

EB Airfoils, LLC

Jet Aviation Specialists, LLC

PAS Technologies Inc

PAS Technologies Romania SRL and

SAComponent Services (Ireland) Ltd

Accel Aviation Accessories, LLC

International Governor Services, LLC

Each Offer shall be deemed a separate contract between the Parties named therein. The Parties acknowledge and agree that any one StandardAero entity shall have no liability nor incur any obligation or be responsible for any failure of any other StandardAero entity to perform its obligations.

Paragraph (a) – Inspection/Acceptance is Reserved. Paragraph (f) – Excusable Delays is replaced with Clause 13 herein. Paragraph (h) – Patent Indemnity is modified as follows: The Contractor shall indemnify the Government and its officers, employees and agents against liability, including costs, for actual or alleged direct or contributory infringement of, or inducement to infringe, any United States or foreign patent, trademark or copyright, arising out of the performance of this contract, provided the Contractor is reasonably notified of such claims and proceedings. The Contractor shall not be liable for breaches or Patent Infringement caused by the OEM. Paragraph (I) – Risk of Loss is replaced with Clause 25 herein. Paragraph (o) – Warranty is replaced with Clause 15 herein. Paragraph (p) – Limitation of Liability is replaced with Clause 18 herein. Clause 26 – Risk of Repair and Clause 19 – Waiver of Claims are to apply to any US Government Orders. In the event FAR 52.212-4 is not applicable, in any event, StandardAero shall apply the above modifications to any like terms within such contract or award.

StandardAero will Redeliver the Components to Customer ExWorks (“EXW” Incoterms 2020) at StandardAero’s facility dock. Customer is responsible for any and all shipping costs (including any import/export duties, import/ export clearance costs, tariffs, applicable taxes, and insurance) to deliver Components from StandardAero’s facility dock to Customer’s facility.

If StandardAero agrees in writing to act as IOR, at its so election and discretion, which can be withheld for any reason, StandardAero may utilize a variety of measures to import the goods. All shipping instructions must be agreed to in writing prior to the inbound shipment. Depending on the transaction, the follow instructions may apply:

To facilitate shipments, Customer shall provide a commercial invoice, or the documentation acceptable in place of a commercial invoice, with the entry and before release of the goods is authorized. The commercial invoice or other acceptable documentation shall contain: 1) an adequate description of the Component(s) including, at a minimum, the part number, serial number, and correct country of origin; 2) the quantity of Component(s) sent, 3) the value or approximate value of the Component or Accessory being sent (e.g. depreciated book value or inventory value), 4) the appropriate eight-digit subheading from the Harmonized Tariff Schedule as per the International Convention on the Harmonized Commodity Description and Coding System done at Brussels on 14 June 1983 and its amendments. Additionally, Customer shall obtain a Certificate of Origin or Certificate of Airworthiness (if applicable) from the OEM and provide it to StandardAero.

Notwithstanding any Incoterms stated herein, in the event that Customer provides a faulty shipping container and StandardAero repairs such container to return the Component, or Customer requires StandardAero to use a shipping container that has been found to not meet StandardAero’s packing specifications, Customer accepts all liability for any loss or damage in transit including for packaging of the Component.

Subject to paragraph (b) below, any Dispute that cannot be amicably settled by the Parties shall be finally settled under the Commercial Arbitration Rules of the American Arbitration Association (the “AAA Rules”), commencing with the filing of a notice of demand for arbitration by either Party following the conclusion of the thirty (30) calendar day period referenced in the paragraph above. Any arbitration will be conducted in accordance with the following: (i) if the Dispute involves a claim for damages totaling at least $5 million (combined with damages alleged in any counterclaim, cross-claim or third-party claim but not including attorneys’ fees or other costs associated with the resolution of the dispute), the Dispute is to be decided by three arbitrators appointed in accordance with the AAA Rules – all other claims are to be decided by one arbitrator appointed in accordance with the AAA Rules; (ii) the arbitrator has no authority to award punitive or other damages beyond the prevailing Party’s actual direct damages and may not, in any event, make any ruling, finding, or award that does not conform to the terms and conditions of the Agreement; (iii) the arbitration award is to be in writing and is to specify the factual and legal basis for the award; (iv) the Parties are to share all fees and expenses of the arbitration equally, with the exception that each Party bears the expense of its own counsel, experts, witnesses, and preparation and presentation of submissions; (v) the arbitration is to be conducted in Phoenix, Arizona unless all Parties agree to a different location; and (vi) the arbitration is to be final and binding and may be entered in any court of competent jurisdiction. A Party’s failure to make a timely demand for arbitration results in the forfeiture of all of the claims and issues that the Party identified in its Dispute Notice.

This Catalog Confidentiality Agreement (“Agreement”) establishes the terms of use, handling, protection, and safeguarding by Customer (“Customer” shall mean the person requesting access to the Catalog and their employer) required for access StandardAero’s prices (“Catalog”) to procure repair and overhaul services (“Services”) from StandardAero (hereinafter the “Purpose”).